Fiber Cement Companies A Market Overview

Fiber cement companies are shaping the building materials landscape, offering durable and versatile products for construction projects worldwide. This exploration delves into the global fiber cement market, examining key players, manufacturing processes, industry trends, and the future outlook for this dynamic sector. We’ll uncover the diverse applications of fiber cement products, from siding and roofing to cladding, and explore the sustainability initiatives driving innovation within the industry.

From understanding the market size and growth projections to analyzing the competitive strategies of leading companies, this overview provides a comprehensive look at the fiber-cement industry. We’ll also investigate the environmental impact of fiber cement production and discuss the challenges and opportunities facing companies in this ever-evolving market.

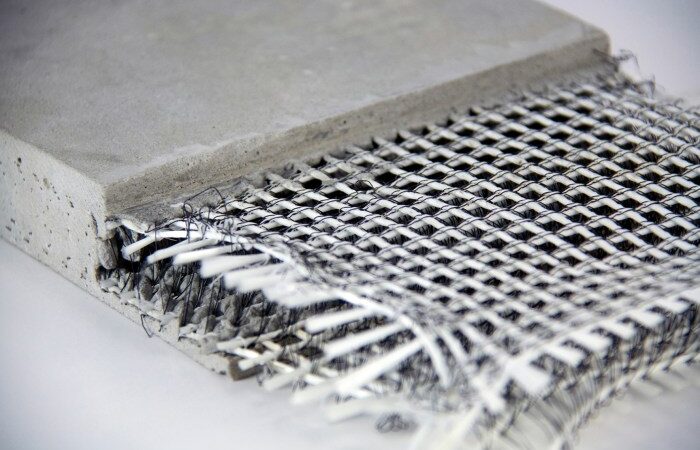

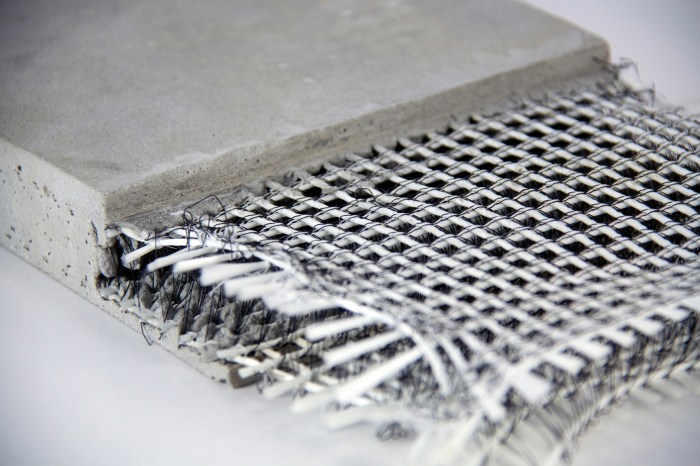

Manufacturing Processes and Technologies

Fiber cement manufacturing is a fascinating blend of industrial processes and material science. The creation of these durable and versatile products involves a precise sequence of steps, leveraging both traditional techniques and cutting-edge technologies to produce high-quality, consistent materials.

The key steps in fiber cement production involve mixing, forming, pressing, curing, and finishing. These stages, while seemingly straightforward, require precise control over variables such as mix proportions, pressure, temperature, and time to achieve the desired product properties. The choice of technology at each stage significantly impacts the final product’s quality, cost, and production capacity.

Raw Material Preparation

The process begins with the careful preparation of raw materials. This includes the precise measurement and blending of Portland cement, cellulose fibers (often wood pulp), silica sand, and water. The quality of these raw materials directly affects the final product’s strength, durability, and appearance. Variations in the composition of the mix can be used to tailor the properties of the final fiber cement product for specific applications. For instance, a higher proportion of cement might be used to increase strength, while adjustments to the fiber content can influence workability and flexibility.

Mixing and Slurry Formation

Once the raw materials are measured, a high-shear mixer thoroughly blends them to create a homogenous slurry. This is a critical step, ensuring consistent distribution of the fibers and other components throughout the mixture. The consistency of the slurry is carefully monitored to maintain optimal workability for the subsequent forming process. The use of advanced mixing technologies ensures uniformity and minimizes the risk of inconsistencies in the final product.

Forming and Pressing, Fiber cement companies

The prepared slurry is then shaped into the desired product form. Traditional methods might involve casting into molds, while modern techniques utilize extrusion processes for continuous production. Regardless of the method, the formed product undergoes significant pressure to remove excess water and compact the mixture. High-pressure pressing is crucial for achieving the required density and strength in the final product. The type of press used, its pressure capabilities, and the duration of the pressing cycle directly influence the product’s final properties.

Curing and Finishing

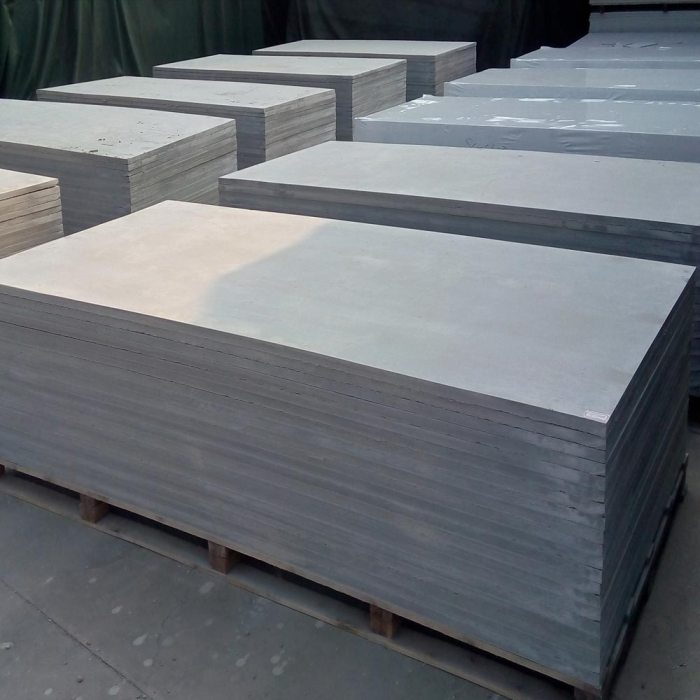

After pressing, the formed fiber cement products are cured to allow the cement to hydrate and harden. This process typically involves controlled temperature and humidity conditions to optimize the cement’s hydration reaction. The curing process significantly impacts the final strength and durability of the product. Modern curing techniques often incorporate accelerated curing methods to reduce production time. Following curing, the products undergo finishing processes such as sawing, cutting, and surface treatment to achieve the desired dimensions and aesthetic qualities. These processes can involve automated machinery for high-volume production.

Manufacturing Technologies: Traditional vs. Modern

Traditional fiber cement manufacturing relied heavily on manual labor and less sophisticated machinery. Modern manufacturing employs advanced automation, including robotic handling systems, automated cutting and finishing equipment, and precise control systems for mixing, pressing, and curing. These modern technologies significantly increase production efficiency, consistency, and product quality while reducing labor costs. For example, the use of extrusion processes allows for continuous production of long lengths of fiber cement sheet, unlike the batch processing often found in traditional methods. The increased precision and automation result in fewer defects and a more consistent final product.

Manufacturing Process Flow Chart

Imagine a flowchart with these boxes connected by arrows:

Box 1: Raw Material Preparation (Cement, Fibers, Sand, Water) –> Box 2: Mixing & Slurry Formation (High-shear mixer) –> Box 3: Forming & Pressing (Casting or Extrusion) –> Box 4: Curing (Controlled Temperature & Humidity) –> Box 5: Finishing (Cutting, Sawing, Surface Treatment) –> Box 6: Finished Fiber Cement Products (Sheets, Boards, Cladding)

Industry Trends and Challenges

The fiber cement industry, while established, is constantly evolving, shaped by technological advancements, shifting market demands, and growing environmental concerns. Understanding these trends and challenges is crucial for manufacturers to maintain competitiveness and sustainability. This section will explore the key factors influencing the industry’s future and how companies are adapting.

Emerging Trends in the Fiber Cement Industry

Several significant trends are reshaping the fiber cement landscape. Increased demand for sustainable building materials is driving innovation in product design and manufacturing processes. The push for higher-performance materials, capable of withstanding extreme weather conditions and offering improved fire resistance, is another key trend. Finally, the integration of smart technologies and digitalization in manufacturing and supply chain management is gaining momentum. This leads to improved efficiency and optimized resource utilization.

Challenges Faced by Fiber Cement Companies

Fiber cement manufacturers face a multitude of challenges, including intense competition from alternative building materials, fluctuating raw material costs (particularly cement and cellulose fibers), and increasingly stringent environmental regulations. These factors necessitate strategic planning and innovative solutions to ensure profitability and long-term viability. Geopolitical instability also impacts the availability and price of raw materials, adding another layer of complexity.

Innovative Solutions Implemented by Companies

Companies are responding to these challenges with a range of innovative strategies. For example, some manufacturers are investing heavily in research and development to create more sustainable and cost-effective production processes, such as exploring alternative fiber sources and reducing energy consumption. Others are focusing on developing high-performance products with enhanced features to command premium prices and differentiate themselves in the market. Supply chain optimization through digitalization and strategic partnerships is also a common response to mitigate raw material price volatility. Some companies are also proactively engaging with regulatory bodies to ensure compliance and advocate for policies that support sustainable manufacturing practices.

Company Responses to Industry Trends and Challenges

| Trend/Challenge | Company Response |

|---|---|

| Increased demand for sustainable building materials | Development of products with recycled content and reduced carbon footprint; implementation of circular economy principles in manufacturing. For example, Company X uses recycled wood fibers in its fiber cement boards, reducing its reliance on virgin timber. |

| Fluctuating raw material costs | Diversification of sourcing strategies; implementation of efficient inventory management systems; exploration of alternative, more readily available, and cost-effective raw materials. Company Y has secured long-term contracts with multiple suppliers to mitigate price volatility. |

| Stringent environmental regulations | Investment in cleaner production technologies; implementation of waste reduction and recycling programs; adoption of sustainable manufacturing practices certified by relevant environmental standards. Company Z has achieved ISO 14001 certification, demonstrating its commitment to environmental responsibility. |

| Intense competition | Focus on product differentiation through innovation and superior quality; development of niche products catering to specific market segments; strengthening brand reputation and customer loyalty through effective marketing and excellent customer service. Company A focuses on high-performance, fire-resistant boards for high-rise buildings, targeting a specialized market segment. |

Environmental Impact and Sustainability: Fiber Cement Companies

Source: alblairconstruction.com

Fiber cement, while a durable and versatile building material, does have an environmental footprint. Understanding its impact, both during production and throughout its lifespan, is crucial for responsible building practices. This section examines the environmental considerations surrounding fiber cement, highlighting sustainability initiatives and comparing its impact to alternative materials.

Environmental Impacts of Fiber Cement Production and Usage

The manufacturing process of fiber cement involves several stages that contribute to its environmental impact. Cement production, a key component, is energy-intensive and releases significant greenhouse gases, primarily carbon dioxide (CO2). The extraction and processing of raw materials like sand and cellulose fibers also consume energy and resources. Furthermore, the manufacturing process may generate waste materials, requiring careful management to minimize environmental harm. The transportation of raw materials and finished products adds to the carbon footprint. Finally, while fiber cement is durable and long-lasting, its eventual disposal can pose challenges depending on local waste management infrastructure. The overall environmental impact is a complex interplay of these factors.

Sustainability Initiatives in the Fiber Cement Industry

Leading fiber cement companies are actively pursuing sustainability initiatives to reduce their environmental footprint. These efforts include investing in more energy-efficient manufacturing processes, such as using alternative fuels and improving kiln efficiency to reduce CO2 emissions. Companies are also exploring the use of recycled materials in their production, like fly ash or recycled cellulose fibers, thereby reducing reliance on virgin resources. Waste management practices are being improved through closed-loop systems that minimize waste generation and maximize recycling. Furthermore, some companies are focusing on developing products with improved lifecycle assessments, considering factors like durability and recyclability at the design stage. For example, Company X has publicly committed to reducing its CO2 emissions by 25% by 2030 through a combination of these strategies.

Comparison with Alternative Building Materials

Comparing the environmental footprint of fiber cement to alternatives like wood, steel, and concrete requires a lifecycle assessment (LCA). While fiber cement’s cement content contributes to its carbon footprint, it often demonstrates a favorable performance compared to certain types of concrete, especially in terms of embodied energy and long-term durability. Wood, while a renewable resource, may have concerns regarding deforestation and transportation distances. Steel production is also energy-intensive, with significant CO2 emissions. The overall comparison depends on several factors, including the specific manufacturing processes, transportation distances, and the material’s lifespan. A comprehensive LCA considering all these factors is essential for accurate comparison.

Hypothetical Eco-Friendly Fiber Cement Production Facility

An eco-friendly fiber cement production facility would prioritize energy efficiency and waste reduction at every stage. This could involve using renewable energy sources like solar or wind power to operate the plant, minimizing reliance on fossil fuels. Waste heat from the manufacturing process could be captured and reused to reduce energy consumption. A closed-loop water system would minimize water usage and prevent wastewater discharge. Raw materials would be sourced sustainably, potentially incorporating recycled materials and minimizing transportation distances. A comprehensive waste management system would ensure that all waste streams are processed responsibly, with materials being recycled or reused wherever possible. The facility would also employ advanced air pollution control technologies to minimize emissions into the atmosphere. This holistic approach would significantly reduce the environmental impact of fiber cement production.

Future Outlook and Potential Growth Areas

Source: Kam-chung.com

The fiber cement industry is poised for significant growth in the coming years, driven by a confluence of factors including increasing demand for sustainable building materials, advancements in manufacturing technology, and the expansion of global construction activities. This growth will be particularly pronounced in developing economies experiencing rapid urbanization and infrastructure development.

The prospects for fiber cement are bright, fueled by its inherent advantages over traditional building materials. Its durability, fire resistance, and versatility make it a compelling choice for a wide range of applications, from residential construction to large-scale infrastructure projects. Further innovation and market penetration will solidify its position as a leading material in the construction sector.

Potential Growth Markets

Fiber cement’s inherent strengths position it for expansion into several key markets. Specifically, the increasing demand for sustainable and eco-friendly building materials will drive significant growth, particularly in regions with stringent environmental regulations. Furthermore, the rising popularity of prefabricated and modular construction methods creates opportunities for fiber cement products tailored to these efficient building techniques. Finally, the need for resilient infrastructure in disaster-prone areas will boost demand for fiber cement’s durability and weather resistance. For example, the increasing frequency of extreme weather events is driving demand for more robust building materials in coastal regions and areas prone to hurricanes.

Technological Advancements in Fiber Cement Manufacturing

Technological advancements are streamlining fiber cement production and enhancing product quality. The adoption of automation and robotics in manufacturing processes improves efficiency and reduces production costs. Research into new fiber types and cement compositions is leading to the development of lighter, stronger, and more sustainable fiber cement products. For instance, the incorporation of recycled materials into the manufacturing process is gaining traction, reducing environmental impact and lowering material costs. Additionally, advancements in surface treatment technologies are resulting in products with improved aesthetics and durability, expanding their design applications. Imagine sleek, modern fiber cement siding with textures mimicking natural stone or wood, all produced with minimal environmental impact.

Timeline of Potential Developments (Next Decade)

The following timeline illustrates potential key developments within the fiber cement industry over the next ten years:

| Year | Predicted Development | Example/Real-life Case |

|---|---|---|

| 2024-2026 | Increased automation and robotics in manufacturing | Major fiber cement producers invest in automated production lines, leading to a 15% increase in production efficiency. |

| 2027-2029 | Wider adoption of recycled materials in production | A leading company launches a new product line made with 30% recycled content, significantly reducing its carbon footprint and gaining a competitive advantage. |

| 2030-2034 | Development of high-performance fiber cement with enhanced properties (e.g., improved strength-to-weight ratio, self-cleaning surfaces) | New fiber cement products are introduced that require less maintenance and offer superior durability, leading to increased market share. |

Epilogue

Source: homedit.com

The fiber cement industry is poised for continued growth, driven by increasing demand for sustainable and high-performance building materials. While challenges related to raw material costs and environmental regulations exist, innovative solutions and technological advancements are paving the way for a more sustainable and efficient future. Understanding the key players, market trends, and manufacturing processes is crucial for anyone involved in or interested in this dynamic sector. The future of fiber cement looks bright, promising both economic opportunity and environmentally responsible building solutions.

Q&A

What are the main raw materials used in fiber cement production?

Typically, cement, cellulose fibers (often wood pulp), and silica sand are the primary ingredients.

How is fiber cement different from other building materials like wood or vinyl?

Fiber cement offers superior durability, fire resistance, and resistance to insects and rot, unlike wood. Compared to vinyl, it’s more robust and less prone to damage from extreme weather.

What are the typical lifespan and maintenance requirements of fiber cement products?

Fiber cement products can last for decades with minimal maintenance, usually requiring only occasional cleaning.

Are there any health concerns associated with fiber cement?

When handled and installed properly, fiber cement poses minimal health risks. However, appropriate safety precautions (like wearing a mask during cutting) should be followed.

How recyclable is fiber cement?

While not directly recyclable in the same way as some materials, many fiber cement products can be repurposed or used as fill material in construction projects.

Comments are closed.